Tec Infrared Grill Parts

In the early 1980s a company known as TEC (Thermal Engineering Corp) invented and patented the infrared grill. But what's so special about IR grilling?

The infrared burner on an infrared grill focuses the flame of a traditional gas burner onto a ceramic tile. This tile is made up of thousands of microscopic holes and is able to transform the heat of the gas burner's flame into infrared radiant energy. Infrared heat is far higher in temperature and more direct than the usual grill, which works by convection heating. While convectional heat is conducted thought air while barbecuing, radiant heat grills directly at the grilling surface with direct heat.

Grilling reproduces the oldest cooking method in the world - an open fire. Whatever fuel is used to produce the flames of a natural fire, there is always a vast amount of infrared energy that is being created, in accordance with the science of physics. From physics we know that any given heat source emits light at some wavelength which is closest to that wavelength of the dominant energy production. To put it simply, the redder a flame the more infrared energy is being produced within it. Wood-burning flames are yellow-orange and coal flames are dull red. But, the gas-fired grill has a blue flame - there's not much infrared energy there at all, and this makes cooking meat thoroughly and efficiently a real problem.

A typical barbeque uses blue-flame burners that need a closed lid to trap air within the barbecuing area. That flames slowly heat the air trapped in the hood until the air is conducting enough heat to cook food. Most barbecues function very much like an oven that can be used outdoors.

Infrared grills also provide moisture retention. Convection heats by heating up the surrounding air and then just pushing that air onto the food. But look what happens when you use a hair dryer - hot air dries out your hair. Convection grills dry out your meats or whatever else you are barbecuing, letting the food's juices rise up and get carried off on the air as condensation or to drip off the food and flare-up. But infrared energy does the precise opposite: it actually drives moisture from the food's surface down deeper into the food, enhancing flavor as well as texture for simply a deeper pleasure in the eating experience.

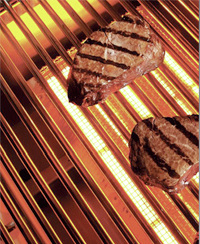

When you use infrared grilling, you get the benefits of shorter grilling times, more convenient grilling, and so much versatility that you can confidently grill even in sub-zero temperatures. Grilling also becomes safer because at very high temperatures any drippings simply get vaporized. This even adds more all-natural flavor to the meat-in short, you don't have flare-ups - due to the infrared designed cooking grate's concave design. But infrared grilling should not be thought of as limited to meats, for just as with convection grilling you can grill anything including seafood, grilled vegetables and chicken. No matter what you're grilling, with infrared grilling technology you get the unsurpassed flavor-enhancement of the wood or charcoal grill merged seamlessly with the pinpoint control and consistency of gas-fired grilling convenience and all the while enjoying more succulent (and thus more nutrition-rich) foods.

Thermal Engineering Corporation, or TEC, introduced the very first infrared grill in 1961. Eventually, their research, development, and engineering prowess led to thirty issued or pending United States and foreign patents. By the 1980s, TEC Grills were making headway as commercial cooking equipment, since they were able to make grills that heated up faster as well as more evenly across cooking surfaces while at the very same time being more fuel-efficient. It was in 1980 that TEC put on the market the world's first under-fired infrared gas grill and this was when professional chefs and restaurateurs really began taking notice and using infrared grills, so that the technology became more widespread than ever before.

However, TEC's main patent on infrared grilling technology ran out in the year 2000-and patents run out to allow for innovation. One new infrared grill making competitor named Altima came up with swappable burner units enabling someone to use a standard burner, infrared burner, and a charcoal firebox all at the same time. Meanwhile, TEC saw two split-offs form from its former employees and management who had ideas of their own: Alfresco and Solaire.

The real objective of all TEC infrared grill making competitors is to create more user-friendly (and sometimes more cost-effective) grills, since the original TEC infrared grills were, of necessity, based more on getting the science and engineering of infrared grilling right than on considerations of customer comfort zones and end-user convenience. The infrared gas grill manufacturer competitors have had much success here.

Alfresco came up with their proprietary "SearZone", which is made up of an infrared burner sitting off to the side of a traditional gas burner. The idea here is that one can use the infrared burner for searing meats, then move the seared meat over to the traditional gas burner to finish the cooking, thereby saving on energy costs, saving on costs for their infrared unit, and theoretically enabling more controlled, refined final flavor of the meat. Alfresco designed and released the first 9 volt ignition module, vented fire box and internal rotisserie motor. However, Alfresco infrared - convection grills (hybrids) use briquettes to conduct heat on the non-infrared, convectional side of the barbeque. Briquettes must be cleaned or swapped often or the stainless below the ceramic briquettes will corrode quickly.

Meanwhile, Solaire has patented its own InfraVection concept intended to allow an easy, user-friendly transition for the grillmaster who doesn't want to leave his "comfort zone" of the traditional convection burner but who still would love to enjoy the benefits of infrared grilling. Just as with Alfresco's "SearZone" technology, the Solaire InfraVection design enables easy conversion from one burner type to another, once again offering the greatest possible control over the final flavor and texture of the food. Solaire also boasts that the convection portion of an InfraVection grill consists of an "efficient stainless steel double-lanced ported U-burner with stainless steel vaporizer plate" (and no briquettes). The valve design on the Solaire infrared and infravection grill models allow both easy removal & installation of infrared and blue-flame burners but also allow an infrared burner to be turned from a low position to a high position without losing its flame.

What this all means for you is that while TEC is still a great brand of infrared griller, you might want to check out other, more user-friendly brands, too, without fearing that you won't be able to get the TEC-developed benefits of the IR grill. But without question, for any grillmaster professional or amateur who can afford it, an infrared grill cannot be surpassed. More than once customers and guests have expressed surprise that the steaks we grill taste much better than the $100. grilled steaks from the best restaurants in town.

The infrared burner on an infrared grill focuses the flame of a traditional gas burner onto a ceramic tile. This tile is made up of thousands of microscopic holes and is able to transform the heat of the gas burner's flame into infrared radiant energy. Infrared heat is far higher in temperature and more direct than the usual grill, which works by convection heating. While convectional heat is conducted thought air while barbecuing, radiant heat grills directly at the grilling surface with direct heat.

Grilling reproduces the oldest cooking method in the world - an open fire. Whatever fuel is used to produce the flames of a natural fire, there is always a vast amount of infrared energy that is being created, in accordance with the science of physics. From physics we know that any given heat source emits light at some wavelength which is closest to that wavelength of the dominant energy production. To put it simply, the redder a flame the more infrared energy is being produced within it. Wood-burning flames are yellow-orange and coal flames are dull red. But, the gas-fired grill has a blue flame - there's not much infrared energy there at all, and this makes cooking meat thoroughly and efficiently a real problem.

A typical barbeque uses blue-flame burners that need a closed lid to trap air within the barbecuing area. That flames slowly heat the air trapped in the hood until the air is conducting enough heat to cook food. Most barbecues function very much like an oven that can be used outdoors.

Infrared grills also provide moisture retention. Convection heats by heating up the surrounding air and then just pushing that air onto the food. But look what happens when you use a hair dryer - hot air dries out your hair. Convection grills dry out your meats or whatever else you are barbecuing, letting the food's juices rise up and get carried off on the air as condensation or to drip off the food and flare-up. But infrared energy does the precise opposite: it actually drives moisture from the food's surface down deeper into the food, enhancing flavor as well as texture for simply a deeper pleasure in the eating experience.

When you use infrared grilling, you get the benefits of shorter grilling times, more convenient grilling, and so much versatility that you can confidently grill even in sub-zero temperatures. Grilling also becomes safer because at very high temperatures any drippings simply get vaporized. This even adds more all-natural flavor to the meat-in short, you don't have flare-ups - due to the infrared designed cooking grate's concave design. But infrared grilling should not be thought of as limited to meats, for just as with convection grilling you can grill anything including seafood, grilled vegetables and chicken. No matter what you're grilling, with infrared grilling technology you get the unsurpassed flavor-enhancement of the wood or charcoal grill merged seamlessly with the pinpoint control and consistency of gas-fired grilling convenience and all the while enjoying more succulent (and thus more nutrition-rich) foods.

Thermal Engineering Corporation, or TEC, introduced the very first infrared grill in 1961. Eventually, their research, development, and engineering prowess led to thirty issued or pending United States and foreign patents. By the 1980s, TEC Grills were making headway as commercial cooking equipment, since they were able to make grills that heated up faster as well as more evenly across cooking surfaces while at the very same time being more fuel-efficient. It was in 1980 that TEC put on the market the world's first under-fired infrared gas grill and this was when professional chefs and restaurateurs really began taking notice and using infrared grills, so that the technology became more widespread than ever before.

However, TEC's main patent on infrared grilling technology ran out in the year 2000-and patents run out to allow for innovation. One new infrared grill making competitor named Altima came up with swappable burner units enabling someone to use a standard burner, infrared burner, and a charcoal firebox all at the same time. Meanwhile, TEC saw two split-offs form from its former employees and management who had ideas of their own: Alfresco and Solaire.

The real objective of all TEC infrared grill making competitors is to create more user-friendly (and sometimes more cost-effective) grills, since the original TEC infrared grills were, of necessity, based more on getting the science and engineering of infrared grilling right than on considerations of customer comfort zones and end-user convenience. The infrared gas grill manufacturer competitors have had much success here.

Alfresco came up with their proprietary "SearZone", which is made up of an infrared burner sitting off to the side of a traditional gas burner. The idea here is that one can use the infrared burner for searing meats, then move the seared meat over to the traditional gas burner to finish the cooking, thereby saving on energy costs, saving on costs for their infrared unit, and theoretically enabling more controlled, refined final flavor of the meat. Alfresco designed and released the first 9 volt ignition module, vented fire box and internal rotisserie motor. However, Alfresco infrared - convection grills (hybrids) use briquettes to conduct heat on the non-infrared, convectional side of the barbeque. Briquettes must be cleaned or swapped often or the stainless below the ceramic briquettes will corrode quickly.

Meanwhile, Solaire has patented its own InfraVection concept intended to allow an easy, user-friendly transition for the grillmaster who doesn't want to leave his "comfort zone" of the traditional convection burner but who still would love to enjoy the benefits of infrared grilling. Just as with Alfresco's "SearZone" technology, the Solaire InfraVection design enables easy conversion from one burner type to another, once again offering the greatest possible control over the final flavor and texture of the food. Solaire also boasts that the convection portion of an InfraVection grill consists of an "efficient stainless steel double-lanced ported U-burner with stainless steel vaporizer plate" (and no briquettes). The valve design on the Solaire infrared and infravection grill models allow both easy removal & installation of infrared and blue-flame burners but also allow an infrared burner to be turned from a low position to a high position without losing its flame.

What this all means for you is that while TEC is still a great brand of infrared griller, you might want to check out other, more user-friendly brands, too, without fearing that you won't be able to get the TEC-developed benefits of the IR grill. But without question, for any grillmaster professional or amateur who can afford it, an infrared grill cannot be surpassed. More than once customers and guests have expressed surprise that the steaks we grill taste much better than the $100. grilled steaks from the best restaurants in town.

TEC Infrared.

Infrared grills have been on the market for just over a decade, though TEC began introducing infrared enhancement into their grills as early as twenty five years ago. The advent of infrared in producing heat for grilling has represented a sea change in the way food is grilled and the results are commensurate with this change.

Understanding heat and how it cooks is essential for understanding the parts of a TEC infrared grill. For those who don't know the differences between heating methods, here is a thumbnail of the various processes. Conduction heating is achieved through direct contact. When a hamburger is placed on a hot surface like a skillet, heat is transferred or conducted directly to the meat. This is different from convection, which transfers heat through a liquid or a gas to the food. Boiled pasta or roasted chicken are examples of convection heating, because the medium (be it water or air) first is heated and in turn transfers the heat to the food being cooked. The third cooking method, radiant heating, is less observable. It entails the direct transfer of energy from the source to the recipient. For example, the sun heats the earth via radiant heating - solar rays carry no heat while traveling through space, but they cause objects with which they come into contact to heat up. There is very little wasted energy involved in this process. Infrared grilling uses radiant heating.

Understanding heat and how it cooks is essential for understanding the parts of a TEC infrared grill. For those who don't know the differences between heating methods, here is a thumbnail of the various processes. Conduction heating is achieved through direct contact. When a hamburger is placed on a hot surface like a skillet, heat is transferred or conducted directly to the meat. This is different from convection, which transfers heat through a liquid or a gas to the food. Boiled pasta or roasted chicken are examples of convection heating, because the medium (be it water or air) first is heated and in turn transfers the heat to the food being cooked. The third cooking method, radiant heating, is less observable. It entails the direct transfer of energy from the source to the recipient. For example, the sun heats the earth via radiant heating - solar rays carry no heat while traveling through space, but they cause objects with which they come into contact to heat up. There is very little wasted energy involved in this process. Infrared grilling uses radiant heating.

In fact the solar example is an excellent metaphor for the process of infrared cooking. The sun is not some laser beam generator - it is a big ball of heat. The same applies to infrared grills. It is a misconception that infrared grills contain some high-tech beam emitter. They actually use gas, but the gas is used to heat a material which in turn emits infrared radiation for cooking. First the gas is turned on to heat an object (say, a ceramic tile) to glowing red. The characteristics of the tile dictate that it will emit radiant heat to cook the food in the grill. Because the tile is so hot, there is some convection heating involved - after all, the atmosphere inside the grill is not the vacuum of outer space. But the majority of cooking is accomplished by the infrared energy being emitted by the heated tile, or whatever object a particular grill uses (TEC's approach is far more advanced, but more on that later). Infrared radiation cooks much more quickly than convection heating, so the food is done in less time than by the convection heating used in traditional grills. The overall time taken in the process from beginning to end is also much less than that in traditional grilling.

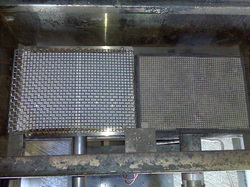

TEC has taken this one step further. To explain, it is necessary to cover charcoal's radiant heat characteristics. Charcoal emits %25 radiant heat. That means that the other %75 of the heat radiated by charcoal is dry, hot air. This dries out the food, which no grill master wants. When TEC first introduced ceramic tile type radiant heating in their grills in the early 80's, the improvement was significant. Those early configurations produced %35 radiant heat from the ceramic tiles - better, but not a game-winning score. Now, TEC has introduced a new element in the form of a high temp radiant glass panel combined with a special stainless steel burner instead of ceramic. The burner produces radiant heat using very small flames. The glass panel in turn equalizes the radiant heat and emits it evenly over the cooking area. It also forces hot air away from the food. Also there are very few flare ups and no hot or cold spots on the cooking surface.

Portable infrared grill by Solaire

With this new approach in materials and design, TEC has achieved a %100 radiant heating coefficient. That means that the heat cooking the food in a TEC grill is being cooked entirely with radiant heat, thereby eliminating moisture loss through convective heat. Additionally, the food browns and carmelizes beautifully (the Malliard Effect). Imagine a well-done steak, with it's deeply grilled flavor, that is also very moist and tender - this is what TEC has accomplished with their new infrared grills. The importance of the radiant glass panel system to infrared grilling cannot be overstated. It wins the game.

Pilot ignition for TEC Sterling II and TEC Patio II is also available with our TEC grill parts

TEC burners old with new replacement burner after repair.

The key advantage of infrared grills is not the speed, but that the infrared energy is able to penetrate the moisture barrier which exists around the food without disturbing it. This invariably results in meat which is moist, tender, and juicy. While there is no doubt that other cooking methods may produce similar results as to moistness, these methods cannot, by their very nature, take full advantage of the Malliard Effect. This effect accounts for the distinctive flavor of grilled meat. The amino acids present in the meat react with reducing sugars to form an array of molecules which account for the blend of flavors that, combined, are recognized (as indeed even prehistoric man recognized) as the taste of well-grilled meat. Infrared grills are able to accomplish this while at the same time minimizing the amount of moisture loss associated with prolonged exposure to high convection heating.

TEC cooking grate replacement.

Replacement TEC cooking grate.

Infrared Gas Grills and High Heat Searing.

Infrared grilling is the process of heating ceramic tiles with either a natural gas or propane until they begin to emulate a thermal radiation that in turn will cook food at a hotter temperature. Unlike a charcoal grill, the infrared grill can reach temperatures of 500 degrees or more. This process allows food to be seared which locks in the juices that traditionally are lost while barbequing and is the main cause of dry meat.

While most barbeques rely on the use of heated air to cook the food on them, the infrared grill radiates and cooks the food directly. The entire process is faster as food is cooked faster, and there is considerably less time for the grill to warm up.

With an infrared grill, the heating surface remains heated uniformly. This means that no matter where you place your food, the temperature will be the same as any other location. Unlike charcoal grills that tend to be hotter where flames are present, and then cool the further away the flame is.

Consider this; in the pouring rain you are unable to use a barbeque because the rain will put out the coals. With an infrared grill you can cook in the hot summer heat, the cold snow of winter and the heavy rains in between. Not even the wind will stop the power of these grills. The mess associated with an infrared grill is minimal compared to other grills. With the infrared grill, a user only has to wipe it down to clean it. With traditional barbeques a user needs to empty out coals, and do a labor intensive cleaning before each use. In 1980 the original infrared grill that was released by Thermal Engineering Corporation. Upon its release TEC had the chance to continue to grow on this basic prototype, as they were backed with a patent that covered them for awhile. The first model designed was very basic. It used the heat of a series of small flames to heat the ceramic plates. While these plates delivered some infrared radiated heat for cooking, there were still flames present and the food was cooked by both means. During the time the ceramic used also had protection issues, and methods of removing the food from them sometimes caused damage. But the technology still was far more advanced than traditional barbequing since there was only a minor chance of a flare-up occurring. What followed in the evolution process were the glass infrared grills. While they remained similar to the previous model, the new technology simply added a glass pane between the ceramics and the food. This almost completely prevented the heated air to reach the food, and enclosed the flames so only the infrared heat would cook the meat. This resulted in tender and juicer foods being cooked, and the glass protecting the ceramics made the cleanup easier and more effective. Finally, in the new generation of infrared grills, all the rules changed. Layers of metal were added to help produce the infrared energy now used to cook the meats. Better formed glass panels are placed over the burners preventing air flow in the grill. All the components on the interior are also setup to produce a uniform heating element, while eliminating the flare-ups that were once possible.

Infrared Grills deliver a better experience than a traditional BBQ on many different levels. Many of the annoyances that people encountered with charcoal are eliminated with the new technique.

Here is a list of all the benefits that are associated with an Infrared Grill:

Traditional means of barbequing also leads to a build up of carcinogens in meat. This is due to the blackening caused by the flames on the grill. With an infrared grill you don't have the direct contact with the flames, which reduces the carcinogens that might end up in your meal. Due to the technology and time it takes to build each infrared grill their price is significantly higher than a traditional grill. The cost of the plates and quality metal also increase the price, so do the heating elements that maintain the uniform heating. But while these grills may be a little pricier, take a few things into consideration.

Less food will potentially be lost during the cooking process because of the uniform cooking. This means that less food is wasted because of it being dried out, or burned during the cooking process.

In time there will be less consumption of fuel so in time you actually start to save money. While the initial cost might startle you, depending on how often you use a grill it can start to save you considerable amounts of money. There is also the fact is will save you time as well. While you need to heat up a barbeque and then watch is every so often and make sure it is working, with an infrared grill that is no longer the case. With a quicker ignition and heating process, you can be grilling your steaks and done in a matter of minutes.

Infrared grills also cool down much faster as well. While a traditional barbeque can take over an hour to cool down, the infrareds tend to cool down much faster. This makes them safer if there are small children in the household, as there is less chance of them being burned in the process.

With the amount of money and time these units save, they are certainly worth the price. Plus with the safety of your family in mind, they tend to cook cleaner and cool faster giving your whole family a safer way to enjoy grilled food.

In closing, when Bill Best created the Infrared Grill decades ago there was no way he could have known the well crafted and effective machines the grills have become these days. With juicier and better tasting food delivered, the world of infrared grilling is only going to get better as time progresses.

While most barbeques rely on the use of heated air to cook the food on them, the infrared grill radiates and cooks the food directly. The entire process is faster as food is cooked faster, and there is considerably less time for the grill to warm up.

With an infrared grill, the heating surface remains heated uniformly. This means that no matter where you place your food, the temperature will be the same as any other location. Unlike charcoal grills that tend to be hotter where flames are present, and then cool the further away the flame is.

Consider this; in the pouring rain you are unable to use a barbeque because the rain will put out the coals. With an infrared grill you can cook in the hot summer heat, the cold snow of winter and the heavy rains in between. Not even the wind will stop the power of these grills. The mess associated with an infrared grill is minimal compared to other grills. With the infrared grill, a user only has to wipe it down to clean it. With traditional barbeques a user needs to empty out coals, and do a labor intensive cleaning before each use. In 1980 the original infrared grill that was released by Thermal Engineering Corporation. Upon its release TEC had the chance to continue to grow on this basic prototype, as they were backed with a patent that covered them for awhile. The first model designed was very basic. It used the heat of a series of small flames to heat the ceramic plates. While these plates delivered some infrared radiated heat for cooking, there were still flames present and the food was cooked by both means. During the time the ceramic used also had protection issues, and methods of removing the food from them sometimes caused damage. But the technology still was far more advanced than traditional barbequing since there was only a minor chance of a flare-up occurring. What followed in the evolution process were the glass infrared grills. While they remained similar to the previous model, the new technology simply added a glass pane between the ceramics and the food. This almost completely prevented the heated air to reach the food, and enclosed the flames so only the infrared heat would cook the meat. This resulted in tender and juicer foods being cooked, and the glass protecting the ceramics made the cleanup easier and more effective. Finally, in the new generation of infrared grills, all the rules changed. Layers of metal were added to help produce the infrared energy now used to cook the meats. Better formed glass panels are placed over the burners preventing air flow in the grill. All the components on the interior are also setup to produce a uniform heating element, while eliminating the flare-ups that were once possible.

Infrared Grills deliver a better experience than a traditional BBQ on many different levels. Many of the annoyances that people encountered with charcoal are eliminated with the new technique.

Here is a list of all the benefits that are associated with an Infrared Grill:

- Less fuel consumption compared to a traditional grill

- Faster heating times. These grills can fully heat in 3 minutes.

- Food is seared to lock in flavors and juices

- Uniform cooking ensures an even cooking to grilled items

- Because of the high temperatures used and the glass cooking surface cleanup is faster and more effective.

Traditional means of barbequing also leads to a build up of carcinogens in meat. This is due to the blackening caused by the flames on the grill. With an infrared grill you don't have the direct contact with the flames, which reduces the carcinogens that might end up in your meal. Due to the technology and time it takes to build each infrared grill their price is significantly higher than a traditional grill. The cost of the plates and quality metal also increase the price, so do the heating elements that maintain the uniform heating. But while these grills may be a little pricier, take a few things into consideration.

Less food will potentially be lost during the cooking process because of the uniform cooking. This means that less food is wasted because of it being dried out, or burned during the cooking process.

In time there will be less consumption of fuel so in time you actually start to save money. While the initial cost might startle you, depending on how often you use a grill it can start to save you considerable amounts of money. There is also the fact is will save you time as well. While you need to heat up a barbeque and then watch is every so often and make sure it is working, with an infrared grill that is no longer the case. With a quicker ignition and heating process, you can be grilling your steaks and done in a matter of minutes.

Infrared grills also cool down much faster as well. While a traditional barbeque can take over an hour to cool down, the infrareds tend to cool down much faster. This makes them safer if there are small children in the household, as there is less chance of them being burned in the process.

With the amount of money and time these units save, they are certainly worth the price. Plus with the safety of your family in mind, they tend to cook cleaner and cool faster giving your whole family a safer way to enjoy grilled food.

In closing, when Bill Best created the Infrared Grill decades ago there was no way he could have known the well crafted and effective machines the grills have become these days. With juicier and better tasting food delivered, the world of infrared grilling is only going to get better as time progresses.